As your business evolves, so do your technology needs. As a result, the systems and processes that worked for you in the past will likely need to be upgraded or changed completely. For some, this means adopting an ERP for the first time. For others, it may mean switching to a system that’s configured specifically for their business so they can leverage all the benefits of an ERP.

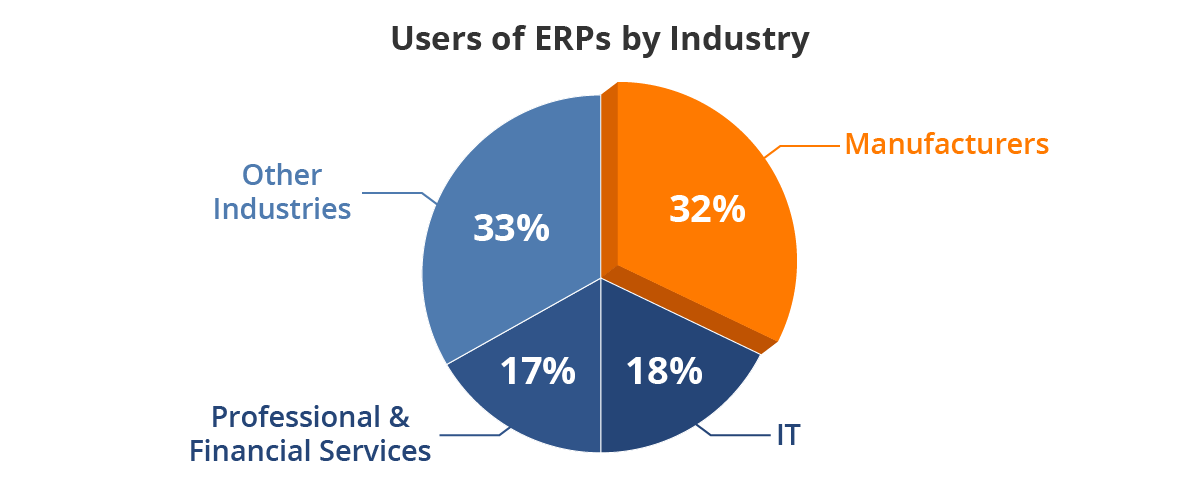

Manufacturers are moving beyond technology’s basic capabilities and are becoming increasingly reliant on integrated technology solutions that allow them to leverage real-time data. As a result, they are beginning to understand the long-term value of a well-implemented ERP solution.

According to Panorama Consulting’s 2019 ERP Report, manufacturers are the number one consumers and users of ERP software. As the industry becomes more technologically advanced, manufacturing companies are investing in the ERP itself and the strategic implementation of a customized solution.

The report also revealed that 65% of SMBs use an ERP consultant such as a Chief Information Officer (CIO) to guide them through the implementation process.

Whether you are implementing an ERP solution for the first time, upgrading, or changing your current solution, you should never make a significant technology change without considering how it will affect your entire organization. For example, suppose you don’t have an in-house CIO. In that case, your outsourced IT Provider should help you understand how to successfully implement the technology to ensure the solution you choose meets your needs and allows you to take advantage of the benefits of an ERP. To do this, they must first understand the problems you are trying to solve and why you want to make the switch.

Why Manufacturers Switch: The Benefits of an ERP

Whether you’re moving on from using QuickBooks as a makeshift ERP, or you want more from the solution you currently have in place, there are many benefits of an ERP, which is the reason why so many manufacturers are making the switch. Some, or all, of the reasons below, may apply to you.

- Your current system is no longer supported: Software companies face the same challenges as any other company. When the demand for a product longer exists, it is not uncommon for these companies to sunset software or discontinues support. When an ERP reaches its End-of-Life (EOL), it doesn’t mean it will be shut down. BUT, it does mean you will no longer have access to upgrades, patches, or the compliance and security automation features designed to defend against new threats that arise. This leaves your business and client data at risk and puts you behind the competition.

Products like the Sage Abra Suite — reaching its EOL in December 2020 – can interrupt business processes by cutting off updates that prevent the software from functioning as it did before. However, manufacturers whose ERP software is still supported and delivering new features can leverage opportunities to stand out in the industry. EOL is a frustrating but common occurrence, especially among smaller software providers, but proactive planning can help minimize business disruption and costs.

#1: You have outgrown your current solution

When you implemented your current system, it may have been the perfect-fit solution. But, as your business evolves, your systems and processes change. In addition, new products may have been released and implemented that don’t tie in with your legacy ERP. When all of these pieces aren’t talking to each other, it negates the benefits of your current solution.

Your ERP should enable you to maintain tight control over your manufacturing processes and materials. This requires integrating with various business units and systems to transfer and source data accurately and efficiently.

For example, suppose someone returned an order because of a product defect. In that case, your ERP should allow you to identify the flaw in the production process, which orders have a defect as a result, and determine whether or not a supplier contributed to the issue. This information would allow you to fix the production error, prevent defective orders from being shipped to customers, and quickly recall the products already delivered before more customers are affected.

#2: Your company is going through a digital transformation

You may have been using manual, outdated, or disconnected technology for each department or business unit until this point. Still, you’re ready to start tying all the pieces together in one solution. As your company matures, so does your need for technology solutions that can help you scale. There are many benefits of an ERP, significantly if your business is growing or improving efficiency throughout the organization. For example, you can streamline employee onboarding and training, enhance production efficiency, automate manual tasks, reduce the risk of errors, avoid customer complaints, and more. In addition, by strategically leveraging its features and customizations, you can leverage opportunities to stand out from your competitors.

#4: It’s more attainable than it used to be

Even though the “e” in ERP stands for enterprise, many high-growth and mid-sized companies are starting to implement ERP solutions that are built just for them. Products like Epicor and Sage were developed specifically for smaller businesses. Even large players like NetSuite and SAP have created ERP solutions specifically for this market.

#5: You need better reporting

When you first implemented your current ERP solution, it probably met the needs of your stakeholders, but over time, the metrics that matter may have changed. If your current solution can’t provide the data you need, you’ll need to make a change. When adequately tied to your manufacturing system, an ERP can help track your orders and their progress, find your chokepoints and recognize opportunities to reduce costs and manage risk. In addition, you can customize your ERP solution to track everything from inventory units to service requests for customer equipment.

These are the main reasons manufacturers consider switching to a new system, but an ERP in itself isn’t the solution to their problems. If you want to leverage the benefits of an ERP, it takes more than your IT team to do so.

Without proper planning and configuration, the technology is just another tool you’re paying for without getting anything in return.

For the solution to deliver the value you expect, you must customize your ERP to speak the language of your business.

Need Help Deciding Which ERP is Right for You?

If your current technology isn’t working for your business, but you don’t know how to choose the best-fit ERP solution, get advice from someone who knows your industry and has the technical knowledge and business insight to guide you along the way.

Researching and selecting the best technology for your business is what our IT consulting services are for. Our CIOs work with your company – from the moment you start thinking about switching to an ERP – to understand what you’re trying to accomplish and why. Because the CIOs are engaged in IT projects from the start, they can research and develop a solution that will continue to deliver value long after its implementation.

At Aldridge, we work with manufacturing firms to help them understand the benefits of an ERP, their options, and which solution will meet their unique needs. Let us help you make the right choice for your business so you can get the most from the ERP you choose.